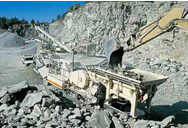

Construction, Working and Maintenance of Crushers for

2018年12月26日 Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use. The goal of a

Онлайн консультация

Feeder Breakers - FLSmidth

The Feeder Breaker is an integral part of the material handling system, and reliably and consistently crushes and breaks down a wide range of material to precise

Онлайн консультация

Coal comminution and sizing - ScienceDirect

2013年1月1日 The objectives of comminution are (1) to break coal to a manageable size for cleaning in a preparation plant, and (2) to reduce it to a fine particle size to meet

Онлайн консультация

Coal Pactors - Mecotra

Coal Pactor Design Concept. The crushing chamber is formed by a pair of curved breaker plate assemblies on opposite sides of the rotor assembly. This rotor assembly includes several rows of forged steel swing

Онлайн консультация

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 The coal handling plant (CHP) in a thermal power station covers unloading of coal, its crushing, storage and filling of boiler bunkers. Coal unloaded in the wagon

Онлайн консультация

Crusher - an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary

Онлайн консультация

What Type of Crusher Is Best for Primary

2021年3月25日 The differences between Standard Hammermills and Non-Clog Hammermills are the breaker plate and the types of materials they process. Standard Hammermills feature a stationary breaker plate and

Онлайн консультация

Ring Granulator Type Coal Crusher - Working

1 天前 Screen plates are made from abrasion resistant steel. 6. Breaker Plate. They are made of Replaceable abrasion resistant steel. The main function of breaker plate is to protect the crusher body from wear. 7.

Онлайн консультация

Roll Crushers Williams Crusher

Williams Patent Crusher Roll Crushers pulverize friable materials, including coal, limestone, clay, and minerals. Typically, the mining, recycling, and power industries use this equipment. Williams is an industry-leading roll

Онлайн консультация

McLanahan Rotary Breakers

Rotary Breakers. Rotary Breakers are among the most suitable pieces of equipment for performing size reduction and scalping off undesirable materials in a single operation.

Онлайн консультация

McLanahan Rotary Breakers

Why McLanahan Rotary Breakers. McLanahan Corporation built the first Rotary Breaker in 1893, and since that time, our design is an evolution of more than 100 years of rotary equipment knowledge. Our overlapping screen plate design is bolted to the inside of the steel cylinder beams to further strengthen and add rigidity to the cylinder.

Онлайн консультация

Roll Crushers Williams Crusher

Williams Crusher designs and manufactures a variety of Roll Crushers that provide efficiency and durability. Browse our full line of Roll Crushers today! ... including a dust-tight design and sealed cover plates for breaker plate

Онлайн консультация

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 these surfaces are known as grinding plates and other may known as rings, hammers, etc. The linkage between crusher rotor and drive assembly are also critical parts. As failure of these linkages will stop crushing. So its Operation and Maintenance at time to time is very important. Different Type of Coal Grade Details Mostly E and F Grade

Онлайн консультация

Crusher - an overview ScienceDirect Topics

Primary coal crusher: These crushers are used for bigger coal sizes and have different types such as the coal jaw crusher, the coal hammer crusher, and the ring granulator. (b) ... The travelling breaker plate prevents any build-up of material in the inlet of the crusher. Any material that remains adhering to the breaker plate is wiped off by ...

Онлайн консультация

Coal Crushers Coal Pulverizers Mills Williams Crusher

These meet the needs of clients worldwide and provide solutions for them every day. Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 433-5464, email us at info@williamscrusher, or near you.

Онлайн консультация

Impactor Parts List Unicast Wear Parts

Coal. Capabilities. OEM Replacement Castings. Quality Control. Metallurgy. Foundries. Case Studies. About. About Unicast. ... Impact Crusher Impactor Hazemag APS2035 Custom Design U1087-10RH Wall Liner, Impact Crusher Impactor ... Breaker Plate Impactor Cedar Rapids 5048 4431-699-03 U2211-2 Feed Chute Liner, Bottom Impactor

Онлайн консультация

Construction Working and Maintenance of Crushers for

2018年12月26日 Wear plates used to protect the crusher frame side plates. They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel. ... For coal, many times, rotary breakers are used as primary crushers and ring granulators are used as secondary crushers. Information on construction and

Онлайн консультация

How Do I Know Which Primary Crusher Is Best For My Coal

2019年10月17日 Generally, a Quad Roll Crusher is recommended for a medium size feed material, while the Triple Roll Crusher, with its single roll top stage, is effective for handling larger size feeds. These machines do the work normally assigned to two separate crushers. Typical feed sizes range from 18” – 72” with final product size of ½” – 3”.

Онлайн консультация

What is the best jaw crusher for coal processing? - LinkedIn

2023年3月16日 Jaw Crusher with Rotary Breaker: This type of crusher has a rotary breaker plate that separates the coal from the rock, and the coal is then crushed between the two jaws. It is suitable for ...

Онлайн консультация

AR-400 BHN Perforated Plates, Grizzly Decks,

Coal Crusher Rotary Breaker Plates: Rotary breaker plates were made from 1” Thk. AR-420 BHN abrasion resistant steel, then cut and formed to required radius. The plates were later drilled and countersunk for a direct

Онлайн консультация

Crushing of coal and calculation of size reduction

2015年2月24日 Generate -0.5 mm particles to the tune of 23 % 2. Minimize + 13 mm particles in Product of the Crusher 3. Generate minimum - 3 mm + 0.5 mm fraction size to maximise the cyclone efficiency. 4. Minimum

Онлайн консультация

KR20200143861A - Coal breaker - Google Patents

The coal crusher according to an embodiment of the present invention comprises: a crusher main body through which coal is introduced into an inner space; a plurality of hammers installed in the inner space of the crusher main body and rotating; a repulsion plate ...

Онлайн консультация

No more blockages. It’s the clinker crusher your process deserves

The Heavy-Duty Roller Breaker is the clinker crusher your process needs. Easily crushes even the biggest boulders in your cooler. ... Gyratory Crusher Wear Plates Jaw Crusher EB and EB Pro Jaw Crusher Liners ... Silo/Filter Probe System for coal mill. Back. Spare and wear parts for gas analysis systems. Back. Gears for conveyors.

Онлайн консультация

Construction, Working and Maintenance of Crushers for

2018年12月26日 Wear plates used to protect the crusher frame side plates. They are made from abrasion resistant (AR) plate (400 to 450 Brinell hardness), also called Boron steel. ... For coal, many times, rotary breakers are used as primary crushers and ring granulators are used as secondary crushers. Information on construction and

Онлайн консультация

Hammer Mills for Material Reduction Williams Patent Crusher

The Traveling Breaker Plate Mill is a non-clog hammer mill. This engineering allows a Slugger Crusher to reduce rock, clay, shale, and bauxite to less than ¾”. It can reduce wet, sticky materials to a size suitable for further refinement. This machine’s self-cleaning breaker plates reduce maintenance and service costs.

Онлайн консультация

sbm/sbm impact crusher coal breaker.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Онлайн консультация

Single Roll Crushers by Pennsylvania Crusher Brand

Single Roll Crusher Models: Type K – suited for the size reduction of materials having a compressive strength of 8,000 p.s.i. or less. Materials crushed typically include coal, petroleum coke, lignite and other friable substances. This model is also employed as a lump breaker for potash, chemicals, salts and similar minerals.

Онлайн консультация

crusher coal breaker plate

The breaker plate of a coal crusher has holes therein so that coal small enough to pass through those holes does so without being acted upon by the rotor. This increases the capacity of the crusher, reduces fines, and conserves power. The plate is oriented such that windage generated by the rotor urges the smaller pieces of coal through the holes.

Онлайн консультация